博文

天大人造超强蚕丝比蜘蛛丝强70%

精选

精选

||

天大人造超强蚕丝比蜘蛛丝强70%

诸平

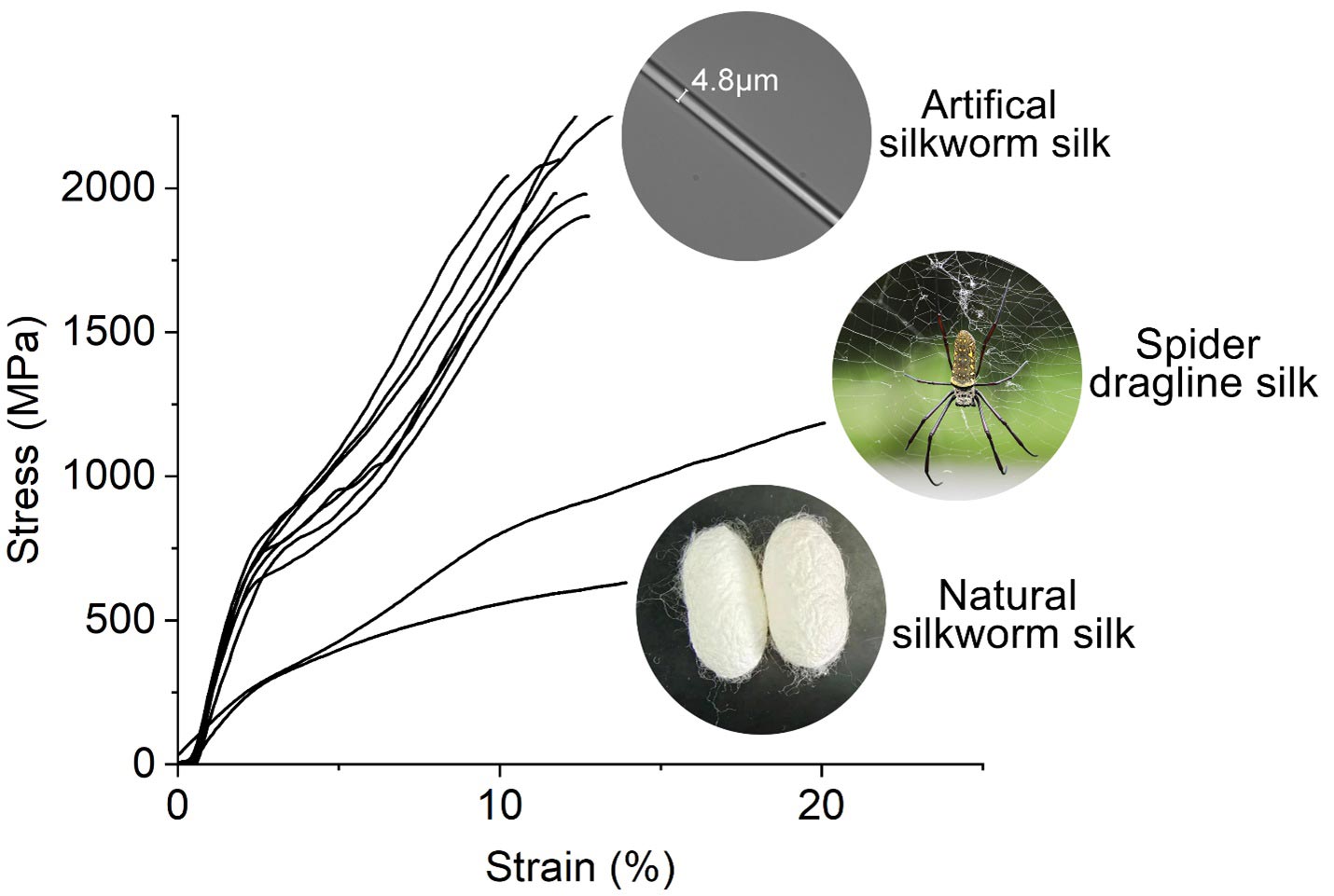

据细胞出版社(Cell Press)2022年10月7日报道,人造超强蚕丝比蜘蛛丝强70%(Artificial Superstrong Silkworm Silk Is 70% Stronger Than Spider Silk)。蜘蛛丝很结实,但很难养殖。新的研究揭示了蚕自然产生的丝要比蜘蛛丝强70%。

尽管蜘蛛占据了最强丝的市场,但它们的侵略性和领土性太强,无法养殖。将蜘蛛DNA整合到蚕中是下一个最佳选择,但这是一个昂贵且难以规模化的过程。

现在,科学家们已经发现,通过去除蚕丝外层的粘性,并手工纺丝,蚕丝的强度可以比蜘蛛丝强70%。相关研究由中国天津大学(Tianjin University)的研究人员完成,于2022年10月6日已经在《物质》(Matter)杂志网站发表——Jingxia Wang, Tiantian Fan, Xi Li, Xiaoxia Hu, Weidong Huang, Wensu Yuan, Zhi Lin. Artificial superstrong silkworm silk surpasses natural spider silks. Matter, Available online 6 October 2022. DOI:10.1016/j.matt.2022.08.028. https://doi.org/10.1016/j.matt.2022.08.028

此论文的通讯作者、天津大学生物化学家林志(Zhi Lin音译)说:“我们的发现扭转了之前认为蚕丝在机械性能上无法与蜘蛛丝竞争的看法。”

从历史上看,蚕丝在时尚界被用作皇室奢华长袍和服装的原材料。然而,今天,在生物医学中更可能发现丝基材料作为缝线和手术网的材料。由于其生物相容性(biocompatibility)、机械性能和生物降解性(biodegradability),它还用于组织再生实验。

生产丝线最常见的方法是养殖蚕。然而,这些丝线不如蜘蛛纺出的丝线耐用或结实,特别是在高张力下自然表现良好的蜘蛛牵引丝(spider dragline silks)。“牵引丝是蜘蛛网的主要结构丝。它还被用作蜘蛛从树上掉下来的生命线,”林志说。另一方面,蚕在转变为飞蛾形态的过程中,会使用其较软的蚕丝来构建棉球状的茧(cotton-ball-like cocoons)。

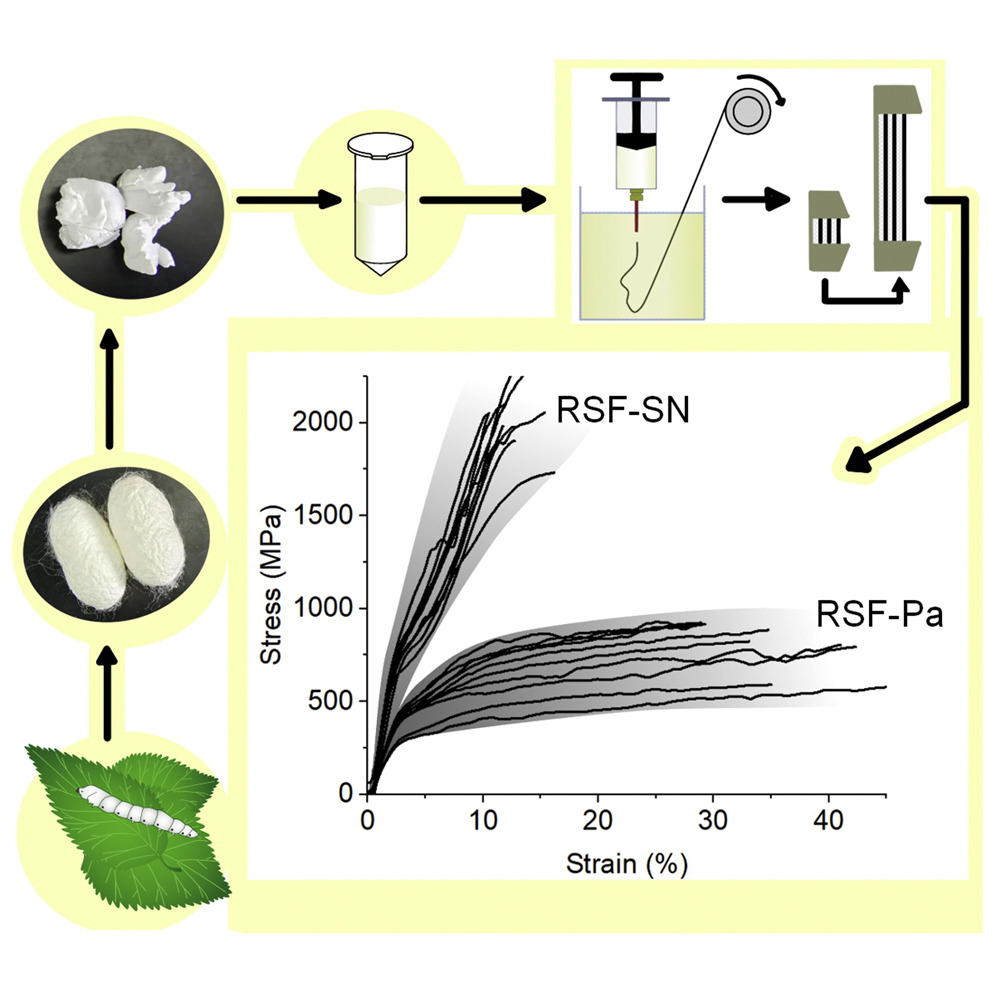

虽然其他科学家已经结合蜘蛛的DNA来制造丝线,但林志的研究小组想要使用更容易获得和更容易管理的普通蚕。他们的灵感来自蜘蛛蛋壳丝(spider eggcase silk)的人工纺丝。蜘蛛蛋壳丝是蚕丝的近亲,并且已被证明在纺丝过程中表现良好。

天然蚕丝纤维是由丝胶包裹的芯纤维组成,它干扰了用于商业用途的纤维的纺丝。为了解决这个问题,科学家们将普通家蚕Bombyx mori的蚕丝放入化学溶液中煮沸,这种化学物质可以溶解这种胶质,同时最大限度地减少蚕丝蛋白的降解。然后,为了增强丝线的纺纱性能,研究小组将丝线在金属和糖浴中固化。

林志说:“由于蚕丝在结构上与蜘蛛蛋壳丝非常相似,之前已证明它在锌和铁混合浴中表现良好,我们考虑测试这种替代方法以避免在其他地方使用的危险条件。蔗糖(Sucrose)是糖的一种,可能会增加凝固浴的密度和粘度,从而影响纤维的形成。”

经手工纺丝和拉丝后,这些蚕丝比原来的蚕丝更细,几乎和蜘蛛丝一样大。在显微镜下观察,林志将其描述为“光滑而结实”,这表明人造纤维可以承受外力。

“我们希望这项工作为生产可盈利的高性能人造丝开辟一条有前景的途径,”林志说。

此研究得到天津大学和中国国家自然科学基金委员会(National Natural Science Foundation of China)的资金支持。

上述介绍,仅供参考。欲了解更多信息,敬请注意浏览原文或者相关报道。

• A facile strategy is developed to spin superstrong artificial silkworm silk

• Artificial silk exhibits ~2.0 GPa in strength and ~40 GPa in stiffness

• High crystallinity and small nano-crystallites are key for superstrong artificial silk

• Incorporation of Zn2+ ions may contribute to silk’s excellent mechanical properties

Silk-based biomaterials from silkworms are widely used in the textile and medical industries. Recently, spider silks have attracted people’s interest due to their much better physical properties compared with silkworm silk. However, it is still quite challenging to synthesize spider silks on a large scale owing to excessively high costs. This study reports a simple and scalable method to produce superstrong silk fibers using regenerated proteins from commercialized silkworm silk. This artificial silkworm silk exhibits a tensile strength of ~2.0 GPa, significantly higher than the strongest natural silk, spider dragline silk. It is also considerably stiffer than any known natural silks. The deliverable from this study reverses the previous perception that silkworm silk cannot compete with spider silks on mechanical performance and thus opens a promising way to produce profitable high-performance artificial silks.

Silks are protein-based biopolymers with unique combinations of different physical properties. Silkworm silk is the most well studied due to its abundance and good mechanical behaviors. However, silkworm silk exhibits a weaker strength than the strongest natural silk, spider dragline silk, which is difficult to be produced on a large scale. Here, a facile strategy is developed for spinning superstrong silk fibers in a metal-ion coagulation bath using regenerated silkworm fibroins. The tensile strength of the artificial silk reaches ~2.0 GPa, more than 70% higher than the average tenacity of dragline silks. It also exhibits an average Young’s modulus of ~43 GPa, significantly higher than any known natural silks. Structural investigation indicates that the extraordinary strength may be ascribed to high crystallinity and small nano-crystallites formed in the artificial fiber. Incorporation of Zn2+ ions into the fiber during spinning and post-spinning drawing processes may also contribute to its excellent mechanical properties.

https://m.sciencenet.cn/blog-212210-1358872.html

上一篇:远紫外线LED可有效杀死细菌和病毒而不伤害人

下一篇:约翰·克劳瑟及首次量子纠缠实验证明背后的故事