博文

ChatGPT 之后:用知识自动化构造知识工作者的知识工厂

||

Citation:

Y. T. Wang, X. Wang, X. X. Wang, J. Yang, O. Kwan, L. X. Li, and F.-Y. Wang, “The ChatGPT after: Building knowledge factories for knowledge workers with knowledge automation,” IEEE/CAA J. Autom. Sinica, vol. 10, no. 11, pp. 2041–2044, Nov. 2023. doi: 10.1109/JAS.2023.123966

The ChatGPT After: Building Knowledge Factories for Knowledge Workers with Knowledge Automation

Yutong Wang, Xiao Wang, Xingxia Wang, Jing Yang, Oliver Kwan, Lingxi Li, Fei-Yue Wang

Briefing: This perspective introduces the concept and framework of knowledge factories with knowledge machines for knowledge workers to achieve knowledge automation for Industry 5.0 and intelligent industries.

Introduction

The big hit of ChatGPT makes it imperative to contemplate the practical applications of big or foundation models [1]–[5]. However, as compared to conventional models, there is now an increasingly urgent need for foundation intelligence of foundation models for real-world industrial applications. To this end, here we would like to address the issues related to building knowledge factories with knowledge machines for knowledge workers by knowledge automation, that would effectively integrate the advanced foundation models, scenarios engineering, and human-oriented operating systems (HOOS) technologies for managing digital, robotic, and biological knowledge workers, and enabling decision-making, resource coordination, and task execution through three operational modes of autonomous, parallel, and expert/emergency, to achieve intelligent production meeting the goal of “6S”: Safety, Security, Sustainability, Sensitivity, Service, and Smartness [6]–[10].

Being a generative AI language model, ChatGPT [11]–[14] adheres to the “Big Problems, Big Models” paradigm [5]. Its training data consists of Common Crawl, a vast collection of textual data from web pages, books, articles, and other publicly available resources, which makes it proficient in addressing general queries. While ChatGPT is trained on a vast array of topics, its depth of knowledge on highly specialized subjects might not match that of dedicated experts in a specific field. It does not have the capability to analyze real-time data or trends either. In view of this, we must advocate a “Small Problems, Big Models” paradigm, training big models [2] with multimodal data from extremely specific subjects. In this way, widely applying these big models in factories for workers during production and other crucial scenarios, we could solve domain-specific queries, and enable real-time analysis of data with continuous learning ability.

Nonetheless, given that small problems should and have traditionally been resolved with small models, why are large models needed? If so, do we have sufficient data to train big models for small problems? In reality, and especially in the current trend, a small problem must be solved together with many surrounding other small problems. Therefore, today we have to address those small problems deeply in vertical and widely in horizontal, thus the need for domain-specific foundation models and the source of big data for their training. Those special big models offer the capacity to holistically evaluate and generate effective and comprehensive solutions for small problems.

Furthermore, we need to structure and organize a new ecosystem to coordinate biological workers, robotic workers, and digital workers for future smart production [15], [16], specifically by building knowledge factories with knowledge machines for knowledge automation. We also need to design corresponding operational processes and assign proper roles for those three types of knowledge workers, so they can work together synergistically and efficiently. Let us address those important issues in the following sections.

Essential Elements of Knowledge Factories

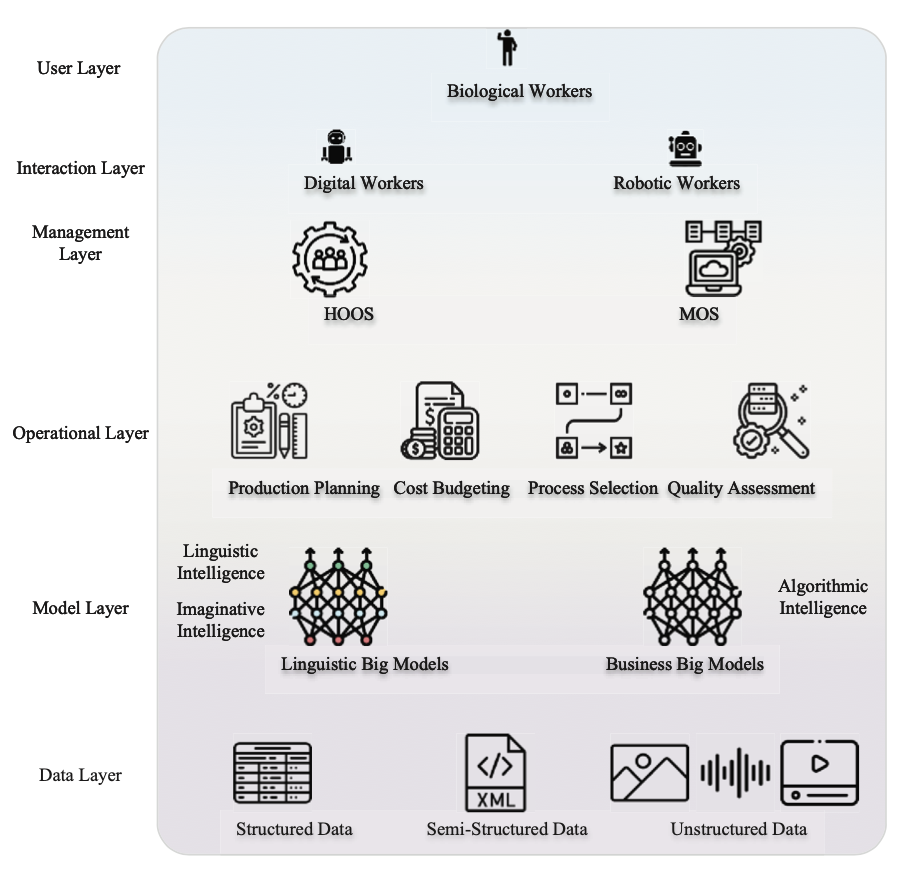

Aiming at knowledge automation [17], the essential elements for knowledge factories include business big models, scenarios engineering, and HOOS. The schematic diagram of the collaboration of these elements in knowledge factories is shown in Fig. 1.

Fig. 1. The collaboration of essential elements for knowledge factories.

● Business big models. Knowledge factories [1], [4]–[7] would involve three types of workers: digital workers, robotic workers, and biological workers, as described in the next section. Business big models are the key technology that assists biological workers and drives digital and robotic workers to execute operational tasks more efficiently and intelligently. They are the cognitive knowledge bases storing domain knowledge and skills for production. Essentially, a knowledge worker itself is a foundation model for special functions in a knowledge factory, and interaction among knowledge workers with business big models is an important issue to be addressed. Note that the theory and method of parallel cognition [18] should be useful in constructing business big models by facilitating the design of efficient Q&A sessions among various knowledge workers and business big models.

● Scenarios engineering. Traditional feature engineeringbased deep learning has achieved the state-of-the-art (SOTA) performance. However, these algorithms are implemented without the in-depth consideration of interpretability, security, and sustainability. Thus, it is impossible to apply these SOTA algorithms to real-world factories directly. In knowledge factories, scenarios engineering [19] can be seen as the integration of industrial scenarios and operations within a certain temporal and spatial range, where a trustworthy aritificial intelligence model could be established by intelligence & index (I&I), calibration & certification (C&C), and verification & validation (V&V). Through the effective use of scenarios engineering, knowledge factories should achieve the goal of “6S” [20], [21].

● HOOS. The primary function of HOOS [22], which is an upgraded version of management and computer operating systems, is to set up task priority, allocate human resources, and make interruptions. With the help of HOOS, workers in the knowledge factories could communicate and cooperate more efficiently, thus greatly reducing the laborious and tedious works and related physical and mental loads to biological workers. Many research on conventional and smart operating systems can be used in HOOS design and implementation [23]–[25].

The Knowledge Workforce: Digital, Robotic, and Biological Workers

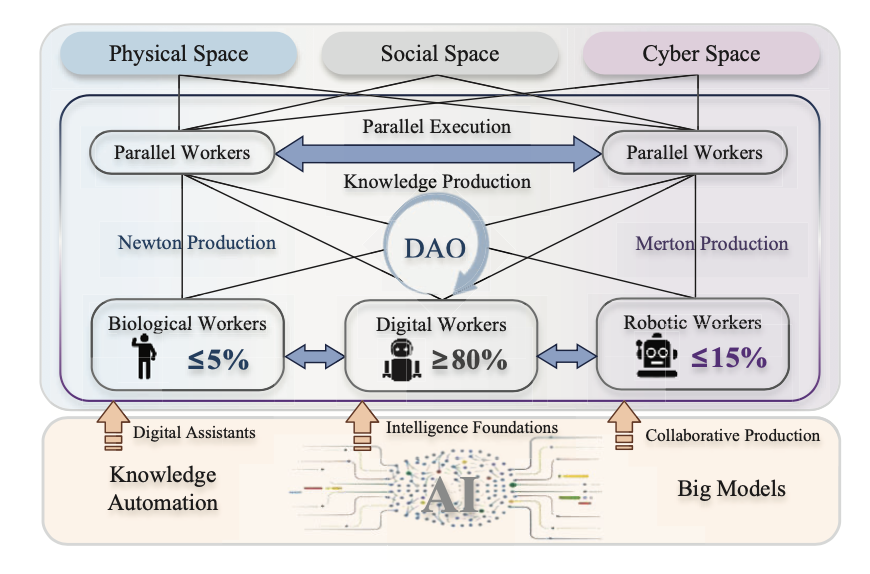

Knowledge workforce in knowledge factories is categorized into three primary classes: digital workers, robotic workers, and biological workers. The interplay of these worker types in knowledge factories is illustrated in Fig. 2. Biological workers are real humans, while robotic workers [26] are designed to aid biological humans in performing complex physical-world tasks, and digital workers are introduced to serve as virtual representations of both biological and robotic workers. The role and function of digital workers encompass facilitating human-machine interactions, coordinating tasks, conducting computational experiments, and other activities that broaden the scopes of both biological and robotic workers [27].

Fig. 2. The knowledge workforce in knowledge factories.

The advancements in foundation model technologies, exemplified by tools like ChatGPT, should accelerate the integration of digital workers in knowledge factories [12], [28]. Digital, robotic, and biological workers interact, align, and collaborate under the DAOs (Decentralized Autonomous Organizations and Decentralized Autonomous Operations) framework [17], [29]. The various elements of physical, social, and cyber spaces interact with each other through digital workers to ensure the completion of required tasks under distributed, decentralized, autonomous, automated, organized, and orderly working environments.

In knowledge factories, digital workers should be the primary source of workforce, facilitating the synergy between biological and robotic workers by automating task distribution and process creation. In our current design, at least 80% of the total workforce should consist of digital workers. Robotic workers, responsible mainly for physical tasks, should make up no more than 15% of the workforce. Biological workers are responsible for decision-making and emergency intervention and should be less than 5% of the total workforce. Knowledge factory utilizes HOOS to achieve interaction and collaboration among three types of knowledge workers. By leveraging the majority of digital and robotic workers, knowledge factories boost efficiency, lessen the strain on biological workers, save resources, and promote sustainable production.

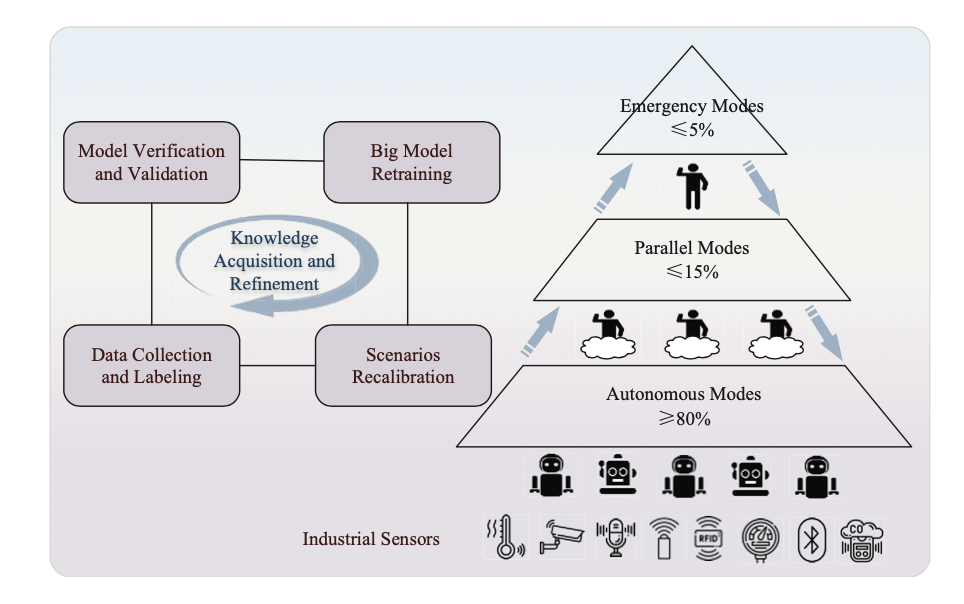

The Process for Knowledge Automation: APeM

The process for knowledge automation involves three distinct working modes: autonomous modes (AM), parallel modes (PM), and expert/emergency modes (EM), collectively known as APeM. These modes play various roles in the workflow of knowledge factories, as described in Fig. 3. AM represents the ultimate concept of unmanned factories. AM should be the primary mode of operations, accounting for over 80% of the production process, requiring mainly the involvement of digital and robotic workers. PM should be activated in fewer than 15% of cases, providing remote access for human experts to resolve any unforeseen issues or failures that arise during production. If an issue persists even after PM deployment, the corresponding production process switches to EM, which accounts for less than 5% of the time, where experts or emergency teams are dispatched to the site to resolve the problem directly. Once the issue is rectified, the production process reverts to PM, monitored remotely for a set duration, and then transitioned back to AM.

Fig. 3. The process for knowledge automation: APeM.

In general, PM should address unpredictable and rare longtail issues in most of production processes. These issues might involve unexpected defects in a production chain or an equipment malfunction. Using this mode, experts can manipulate robotic workers and identify problematic areas through anomaly detection and diagnosis during remote access operations. Nonetheless, some production challenges elude solutions via PM, especially if the data is not accessible by industrial sensors or robotic workers, or if robotic workers cannot emulate specific human actions. In such cases, the data in actual factories should be collected and labeled, and related scenarios need to be recalibrated. Big models undergo iterative retraining as new data is introduced, and perform verification and validation to ensure the revised models are up to par. Knowledge acquisition and refinement will then be achieved as modes are toggled.

Conclusion Remarks

This article presents the framework of building knowledge factories with knowledge machines for knowledge automation by knowledge workers. Equipped with domain-specific big models, digital and robotic workers would assist biological workers to perform decision-making, resource coordination, and task execution. Through knowledge processing under AM, PM, and EM, big models are iteratively optimized and verified through scenarios engineering and acquire new knowledge and refine its knowledge base.

Current big models lack the ability to defend against malicious attacks, as well as the capability to reason about complex problems. In the future, for trustworthy and explainable knowledge factories, it is essential to incorporate federated intelligence and smart contracts technologies in constructing and training big models to ensure their safety, security, sustainability, privacy, and reliability.

ACKNOWLEDGMENT: This work was partially supported by the Science and Technology Development Fund of Macau SAR (0050/2020/A1).

References

[1] F. -Y. Wang, “New control paradigm for industry 5.0: From big models to foundation control and management,” IEEE/CAA J. Autom. Sinica, vol. 10, no. 8, pp. 1643–1646, 2023. doi: 10.1109/JAS.2023.123768

[2] J. Wang et al., “A framework and operational procedures for metaverses-based industrial foundation models,” IEEE Transactions on Systems, Man, and Cybernetics: Systems, vol. 53, no. 4, pp. 2037–2046, 2022.

[3] X. Li, Y. Tian et al., “A novel scenarios engineering methodology for foundation models in metaverse,” IEEE Transactions on Systems, Man, and Cybernetics: Systems, vol. 53, no. 4, pp. 2148–2159, 2022.

[4] J. Yang, S. Li et al., “DeFACT in manuverse for parallel manufacturing: Foundation models and parallel workers in smart factories,” IEEE Transactions on Systems, Man, and Cybernetics: Systems, vol. 53, no. 4, pp. 2188–2199, 2022.

[5] J. Lu, X. Wang et al., “Parallel factories for smart industrial operations: From big AI models to field foundational models and scenarios engineering,” IEEE/CAA J. Autom. Sinica, vol. 9, no. 12, pp. 2079–2086, 2022. doi: 10.1109/JAS.2022.106094

[6] X. Wang, J. Yang et al., “Steps toward industry 5.0: Building “6S” parallel industries with cyber-physical-social intelligence,” IEEE/CAA J. Autom. Sinica, vol. 10, no. 8, pp. 1692–1703, 2023.

[7] F. -Y. Wang, J. Yang et al., “Chat with ChatGPT on industry 5.0: Learning and decision-making for intelligent industries,” IEEE/CAA J. Autom. Sinica, vol. 10, no. 4, pp. 831–834, 2023. doi: 10.1109/JAS.2023.123552

[8] J. Li, R. Qin et al., “Logistics 5.0: From intelligent networks to sustainable ecosystems,” IEEE Transactions on Intelligent Vehicles, vol. 8, no. 7, pp. 3771–3774, 2023. doi: 10.1109/TIV.2023.3295796

[9] L. Chen, J. Xie et al., “Mining 5.0: Concept and framework for intelligent mining systems in CPSS,” IEEE Transactions on Intelligent Vehicles, vol. 8, no. 6, pp. 3533–3536, 2023. doi: 10.1109/TIV.2023.3285417

[10] Y. Chen, H. Zhang et al., “Society-centered and DAO-powered sustainability in transportation 5.0: An intelligent vehicles perspective,” IEEE Transactions on Intelligent Vehicles, vol. 8, no. 4, pp. 2635–2638, 2023. doi: 10.1109/TIV.2023.3264585

[11] F. -Y. Wang, Q. Miao et al., “What does ChatGPT say: The DAO from algorithmic intelligence to linguistic intelligence,” IEEE/CAA J. Autom. Sinica, vol. 10, no. 3, pp. 575–579, 2023.

[12] J. -W. Lu, C. Guo et al., “The ChatGPT after: Opportunities and challenges of very large scale pre-trained models,” Acta Automatica Sinica, vol. 49, no. 4, pp. 705–717, 2023.

[13] J. Zhou et al., “ChatGPT: Potential, prospects, and limitations,” Frontiers of Information Technology & Electronic Engineering, pp. 1–6, 2023.

[14] Y. Gao, W. Tong et al., “Chat with ChatGPT on interactive engines for intelligent driving,” IEEE Transactions on Intelligent Vehicles, vol. 8, no. 3, pp. 2034–2036, 2023.

[15] X. Wang, J. Yang et al., “Metaverses and demetaverses: From digital twins in CPS to parallel intelligence in CPSS,” IEEE Intelligent Systems, vol. 37, no. 4, pp. 97–102, 2022.

[16] F. -Y. Wang, “Parallel intelligence in metaverses: Welcome to Hanoi!” IEEE Intelligent Systems, vol. 37, no. 1, pp. 16–20, 2022.

[17] F. -Y. Wang, “The DAO to metacontrol for metasystems in metaverses: The system of parallel control systems for knowledge automation and control intelligence in CPSS.”

[18] P. Ye et al., “Parallel cognition: Hybrid intelligence for human-machine interaction and management,” Frontiers of Information Technology & Electronic Engineering, vol. 23, no. 12, pp. 1765–1779, 2022.

[19] X. Li, P. Ye et al., “From features engineering to scenarios engineering for trustworthy AI: I&I, C&C, and V&V,” IEEE Intelligent Systems, vol. 37, no. 4, pp. 18–26, 2022.

[20] F. -Y. Wang, Y. Tang, and P. J. Werbos, “Guest editorial: cyber–physical–social intelligence: toward metaverse-based smart societies of 6I and 6S,” IEEE Transactions on Systems, Man, and Cybernetics: Systems, vol. 53, no. 4, pp. 2018–2024, 2023.

[21] Y. Shen, Y. Liu et al., “Parallel sensing in metaverses: Virtual-real interactive smart systems for “6S” sensing,” IEEE/CAA J. Autom. Sinica, vol. 9, no. 12, pp. 2047–2054, 2022.

[22] F. -Y. Wang, “Parallel management: The DAO to smart ecological technology for complexity management intelligence,” Acta Automatica Sinica, vol. 48, no. 11, pp. 2655–2669, 2022.

[23] L. Chen et al., “Parallel mining operating systems: From digital twins to mining intelligence,” in IEEE 1st International Conference on Digital Twins and Parallel Intelligence (DTPI). IEEE, 2021, pp. 469–473.

[24] Y. -J. Wang, F. -Y. Wang et al., “Parallel hospitals: From hospital information system (HIS) to hospital smart operating system (HSOS),” Acta Automatica Sinica, vol. 47, no. 11, p. 25852599, 2021.

[25] F. -Y. Wang, “Parallel doctors and parallel hospitals: Impact and perspective of chatgpt-like AIGC and AGI on medicine and medicare,” Medical Journal of Peking Union Medical College Hospital, vol. 14, no. 4, pp. 673–679, 2023.

[26] F. -Y. Wang and Y. Gao, Advanced studies of flexible robotic manipulators: modeling, design, control and applications. World Scientific, 2003, vol. 4.

[27] P. Ye and F. -Y. Wang, “Parallel population and parallel human—a cyberphysical social approach,” IEEE Intelligent Systems, vol. 37, no. 5, pp. 19–27, 2022.

[28] J. Yang, X. Wang et al., “Parallel manufacturing for industrial metaverses: A new paradigm in smart manufacturing,” IEEE/CAA J. Autom. Sinica, vol. 9, no. 12, pp. 2063–2070, 2022.

[29] F. -Y. Wang, W. Ding et al., “The DAO to DeSci: AI for free, fair, and responsibility sensitive sciences,” IEEE Intelligent Systems, vol. 37, no. 2, pp. 16–22, 2022.

https://m.sciencenet.cn/blog-2374-1408073.html

上一篇:[转载]第十一届中国指挥控制大会迎来精彩主题报告会

下一篇:[转载]喜报:《指挥与控制学报》入选“中国学术期刊影响因子年报”Q1区